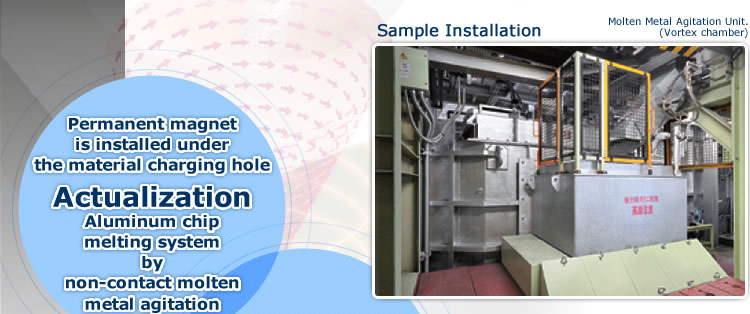

Melting Furnace Non-contact Style

PERMANENT MAGNET TYPE ALUMINUM CHIP MELTING SYSTEM

Advantages of molten metal agitation

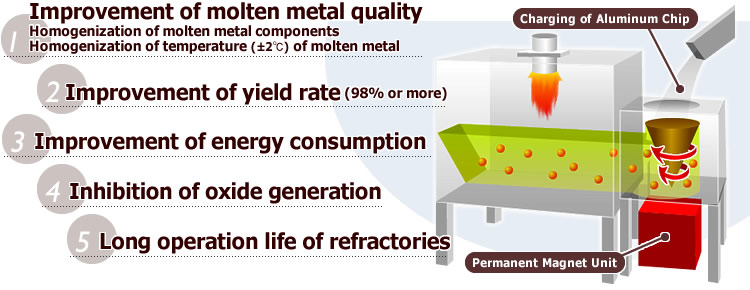

Improvement of molten metal quality

Improvement of molten metal quality

Homogenization of molten metal components

Powerful circulation makes the adjustment of composition easy.

Component segregation can be adjusted extremely small for both circumferential direction and depth direction.

Perfect for use as a furnace for the adjustment of composition of molten metal

Homogenization temperature (±2℃) of molten metal

Heat transfer volume from the burner is improved by circulation function. Molten metal temperature can homogenize for both the circumferential direction and depth direction.

Improvement of yield rate (98% or more)

Improvement of yield rate (98% or more)

Charged melting materials of vortex chamber can keep 98% or more yield rate because materials will be convoluted at once into molten metal without oxidation.

Improvement of energy consumption

Improvement of energy consumption

Gas consumption is cut by 20% by homogenization of molten metal temperature and atmosphere temperature. (Comparison with our products)

Inhibition of oxide generation

Inhibition of oxide generation

Generation of oxide can be inhibited. (Homogenization of molten metal temperature can prevent overheating of molten metal and therefore inhibit molten metal oxidation.)

Long operation life of refractories

Long operation life of refractories

Refractories can be long operation life. (Homogenization of molten metal temperature can prevent overheating of molten metal and therefore inhibit refractory reduction.)

Purpose

●Melting of aluminum chips, machining chips, UBC and solid biscuit

●Powerful circulation makes the unit perfect for use as a furnace for the adjustment of composition of molten metal.

- ●Circulation power can control stepless adjustment and maintain stable power.

- ●Continuous melting and unmanned operation is possible.

- Materials can be melted continuously without need for monitoring operators.

- ●The molten metal agitation unit can be installed as an extension for the existing melting and holding furnace.

Cost performance of aluminum chip reclamation with our permanent magnet type aluminum chip melting system

*The numerical values below are approximate calculations and will differ according to conditions of customer use.

| Processing volume | ||

|---|---|---|

| 300kg/hr(1,150ton/year) | 500kg/hr(1,920ton/year) | |

| Comparison with reclamation ingot purchase | ¥60,700,000/year | ¥148,400,000/year |

| Comparison with molten metal purchase | ¥83,700,000/year | ¥186,800,000/year |

Comparison with traditional chip melting system

Unnecessary spare parts (consumable goods) and maintenance work

Electromagnetic induction agitation system requires spare parts including water cooling device, coil

etc. and maintenance work. Machine agitation system requires spare parts including impeller, pump

etc. and maintenance work.

Power consumption about 1/10 (Compared with electromagnetic induction agitation system)

Molten metal circulation can be trouble-free operation at the touch of a button thanks to the simple configuration.

Smaller footprint

About a 50% reduction in footprint size is possible because our heating and holding chamber has concomitant vortex chamber only. (Compared with electromagnetic induction agitation system or machine agitation system)

Changes of internal furnace environment via molten metal agitation

By Nihon Kohnetsu Industrial Co., Ltd.

Specification List

| Type | PM200 | PM300 | PM500 | PM1000 |

|---|---|---|---|---|

| Processing Volume | ~200kg/hr | ~300kg/hr | ~500kg/hr | ~1000g/hr |

| Electric Power | 2.2kW | 3.7kW | 5.5kW | 11kW |

*Detailed specifications will be decided on order

Options

- Regenerative Burner (Gas consumption: 35% cut - compared with gas burner)

- Non-contact type level sensor (Automatic control of melting volume, Molten metal volume indication)

- Automatic air-to-fuel ratio control

This system has been a commercial realization through a partnership with Zmag.

Zmag has developed the world's first non-contact style permanent magnet type aluminum chip melting system.

![]() Catalog download

Catalog download

PDF:1.7MB

In order to view pdf file, you will need a pdf reader such as Adobe Reader.

If you cannot view the catalog, you need to download Adobe Reader.